LiFePO4 Battery - Support and Development Board

This board is principally designed to hold a 32700 sized battery in place, and make electrical contact with it. For some reason battery holders for this battery are either not available, or are unsuitable. The 32700 naming convention equate to 32mm diameter, and 70mm long (why extra zero?).

As a PCB was being manufactured for this purpose, I (as always) decided to make it multipurpose, by adding some resistor signal conditioning, and by adding prototyping areas to the board. The board does also have a cut-out to cater for a barrel-jack connector, to allow the battery to be charged in-situ.

These batteries have some big advantages over other batteries

- They have about twice the lifetime of conventional Lithium batteries (2000 recharge cycles)

- The 32700 format provides a considerable amount of power, reducing recharging frequency

- The output voltage is directly compatible with modern electronics, which requires a 3.3V input

32700 Battery

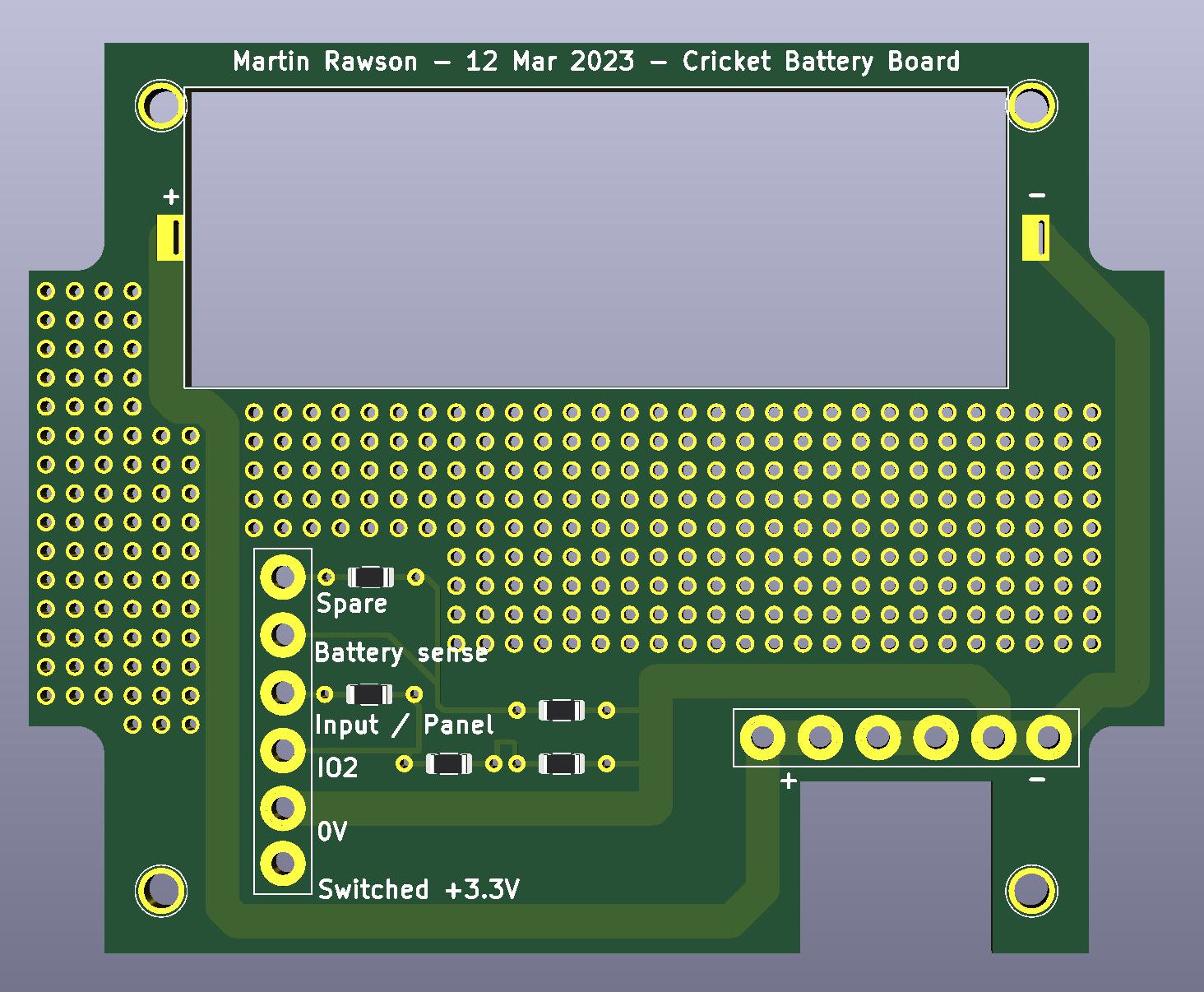

PCB as designed

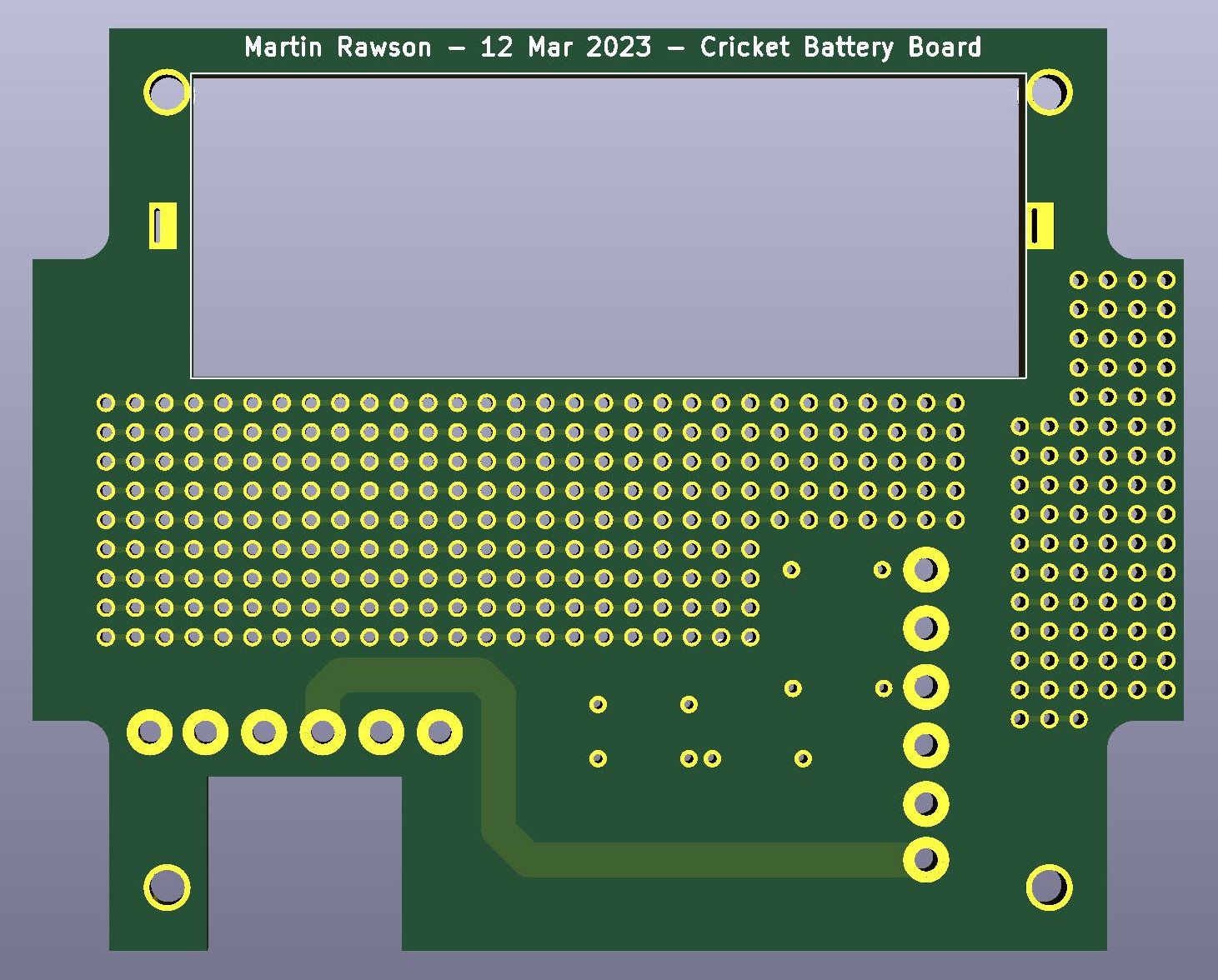

The PCB design is a 1.6mm thick board, double sided and through hole plated board.

The intended use is as a supplementary board to a main board with a micro-controller fitted. Extensive breadboarding (vero style) is provisioned, so the board can be used for self contained projects if desired.

Provision for SOT or axial resistors is also provided, these are optional for signal conditioning the battery voltage, and other parameters used by the Cricket 2 boards.

Front View

Back View

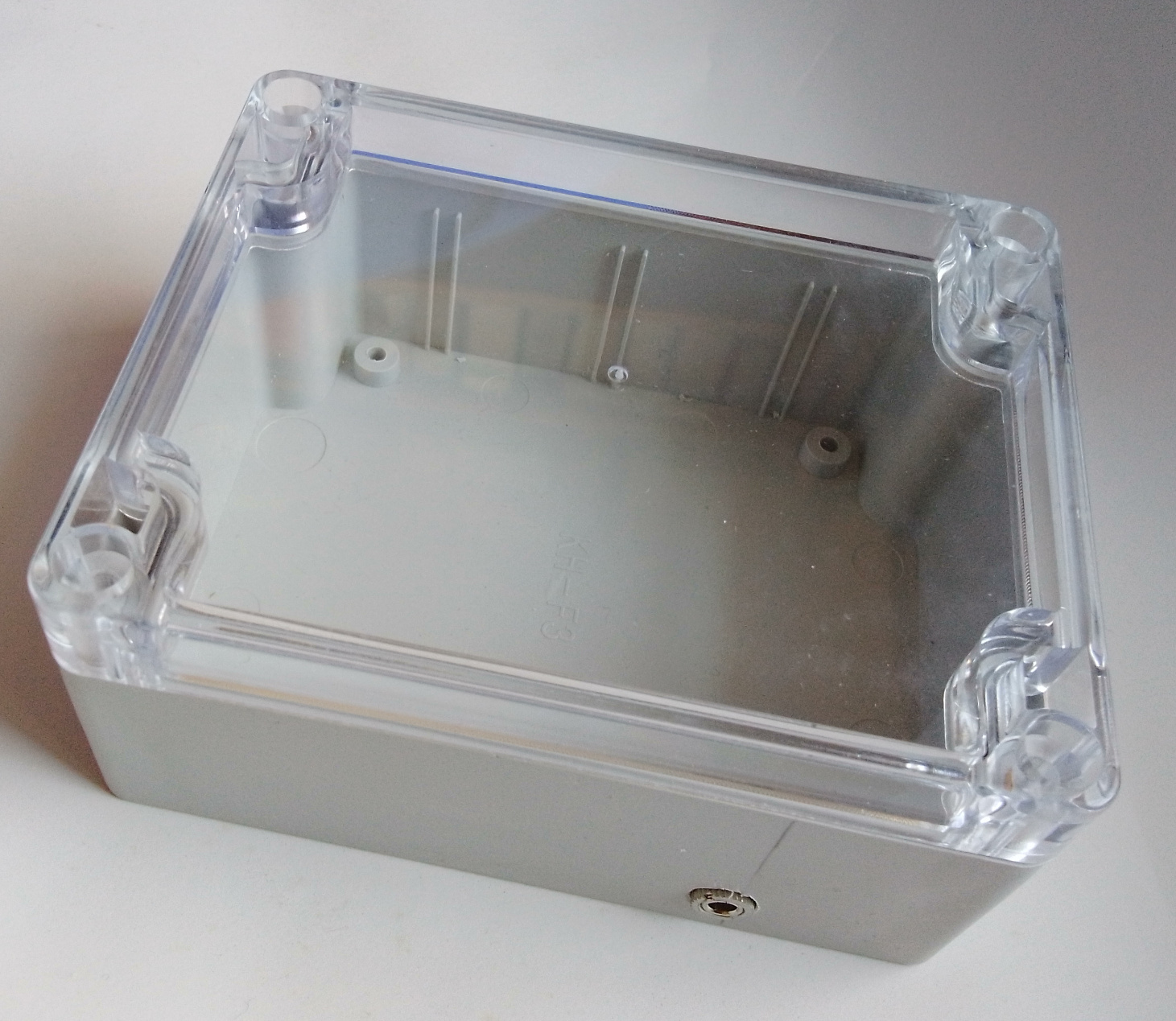

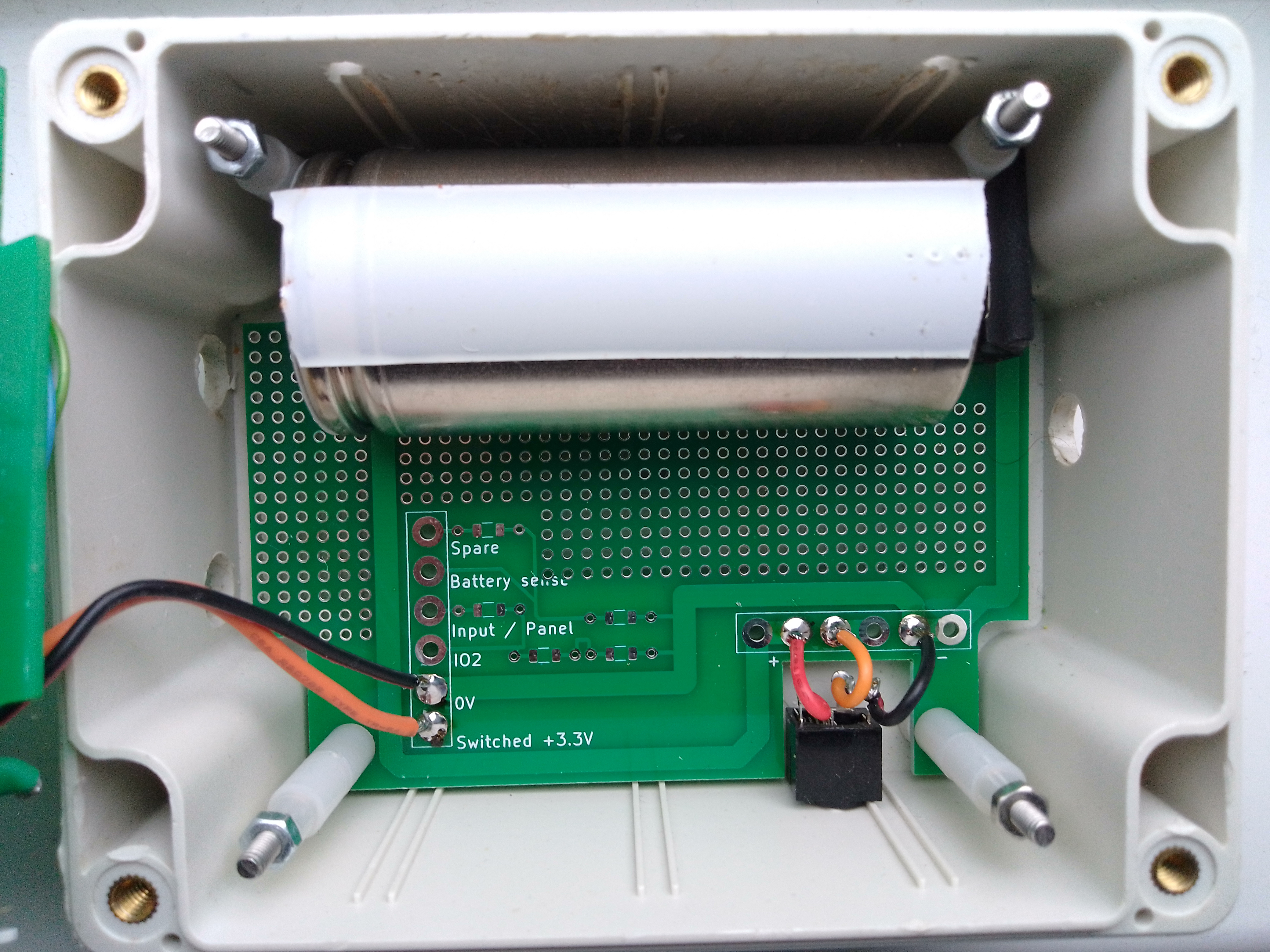

PCB Housing

The case is a standard Chinese 115x90x55 plastic box. The battery board and main board are stacked in pillars, and the LiFePO4 battery is sandwiched between them.

This view of the case shows the 3.5mm socket fitted, which will later be used to charge the battery.

Case 115x90x55

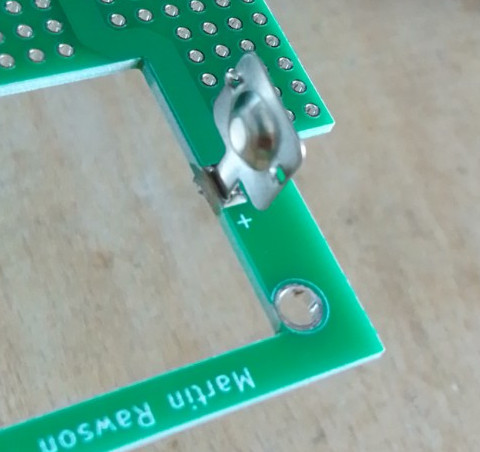

Soldering Steps

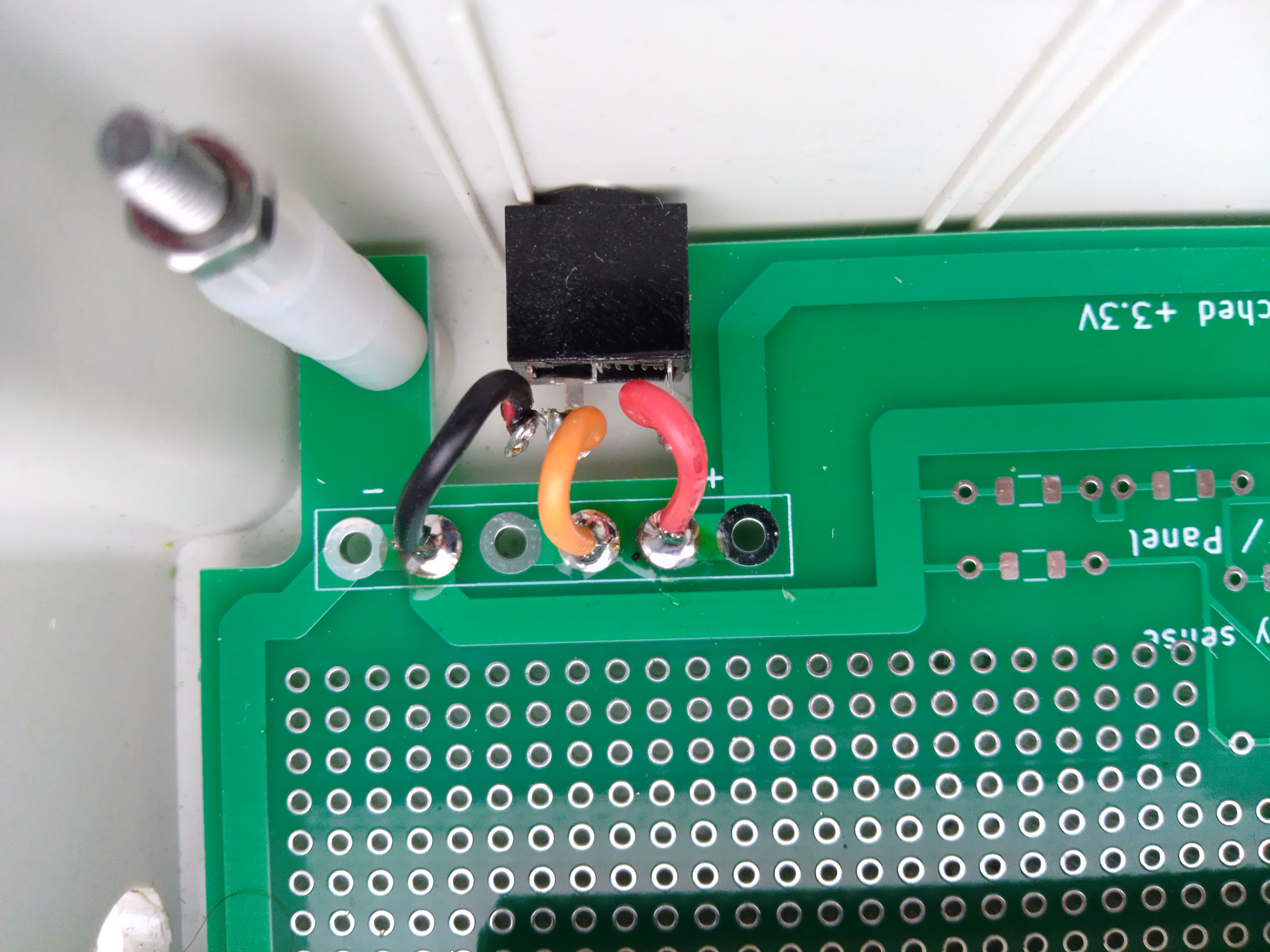

The battery clips are difficult to solder. For a good contact with the battery the clip needs to sit proud of the PCB.

Fitting the clip and using a small wire to hold the clip in place when the board is upside down was found to make the soldering/assembly process much easier, as the clip automatically fell into alignment.

The 3.5mm socket can be pre-fitted to the board, and soldered in-place, then it needs to installed in it’s socket, at the same time as the board is fitted on it’s mounting screws.

Use wire so clip hangs perpendicular to board

-Ve connector

+ve connector

Fitting Components

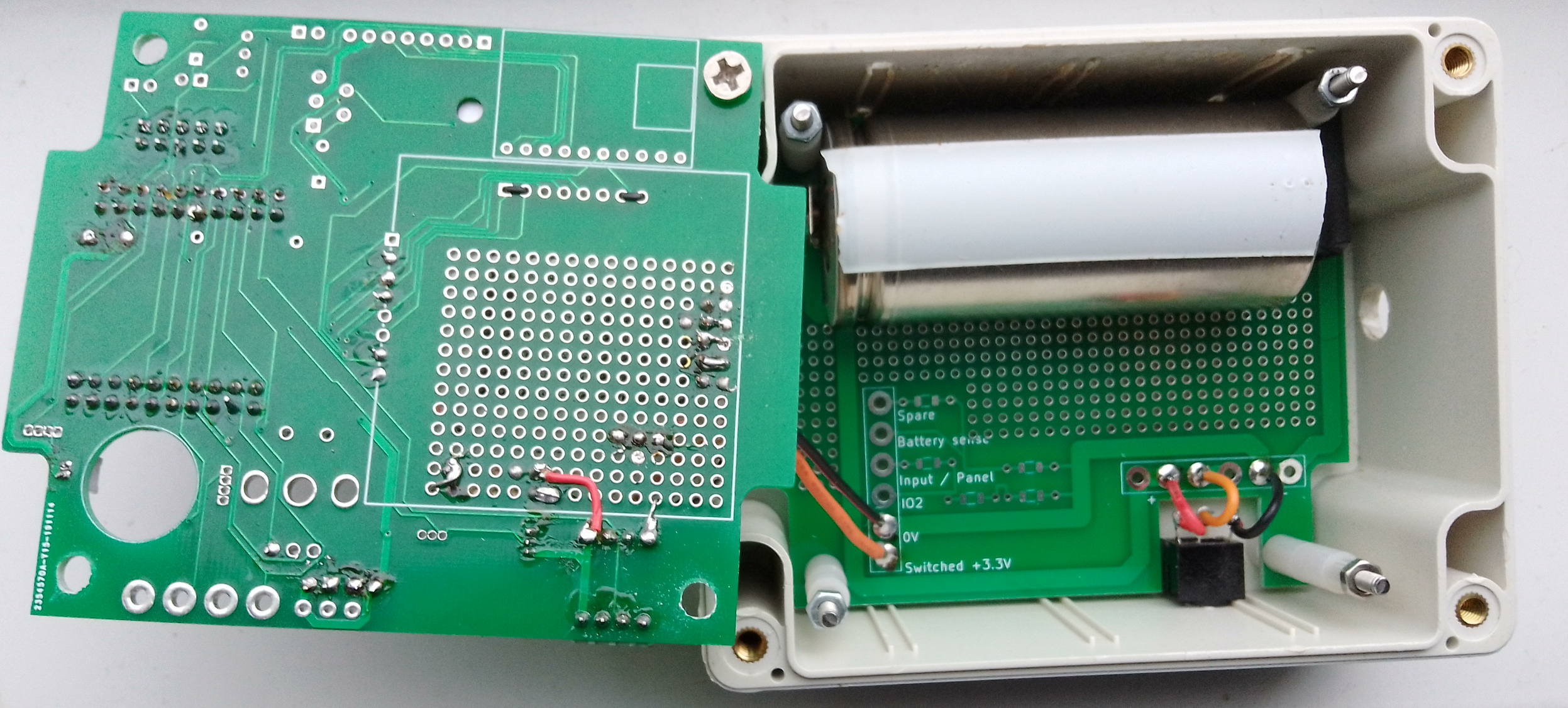

Four 45mm M3 screws hold and support the PCBs, the assembly order is:

Cricket Battery PCB + M3 Nuts + 10mm spacer + 10mm spacer + 4mm spacer + Cricket IOT PCB

The -ve clip with it’s spring does experience a lot of force when the battery is fitted, this causes it to bend, so a plastic filler is used to support the clip, and help mantain pressure on the battery.

The +ve clip also needs support, so a plastic filler with a gash PCB piece is used to support the clip.

The battery clip supports can be hot glued in place.

View showing filler peice behind -ve connector

The pillars will then need to be fitted to support the main PCB. A single 3.3V connection is made between the two boards.

The main board may optionally have an external DS18B20 external temperature probe.

Many of the batteries I have do not have a plastic sleeve, on these batteries I’ve placed an insulating strip along the top of the battery to block contact with the underside or the Cricket PCB.

Case View showing 3.5mm socket

Assembled Cricket Module

Partial assembled view

The 3.3V connection attaches to the main board via its J4 connector, 0V = Pin 1, 3.3V = Pin 4.

The mounting screws are M3 45mm long, and the stacking pillars are 25mm long.

View showing assembly with Cricket2 board connected

More Information on the Cricket2 project can be found in the “2023-03-28-Cricket 2 - IOT Device” blog entry.

Keep it simple, the Cricket 2 modules are designed to have a minimum battery life of 3 months between recharges. That is based on the module doing a transmission every ½ hour, so 2 x 24 x 92 transmission approx 3500 transmissions.

Applicable Links

Battery Manufacturer page www.liitokala.com.cn.

Battery Technology page www.batteryequivalents.com.

Battery Contact Clips page www.aliexpress.com.